Despite the rotating packed bed technology being over half a century old and having been extensively researched in the last decades, many aspects of the apparatus remain unknown. Although RPB is steadily gaining interest in both academia and industry, and numerous novel applications are developed all the time, the technology suffers from lack of understanding at the basic level.

It is well known that RPB, with the use of centrifugal acceleration, provides vigorous micro-mixing and highly developed mass transfer area in a very compact design, thus being an attractive alternative to traditional, stationary packed beds. However, the process being based on phase contact within a rapidly spinning rotor poses many issues regarding comprehensive understanding of its nature.

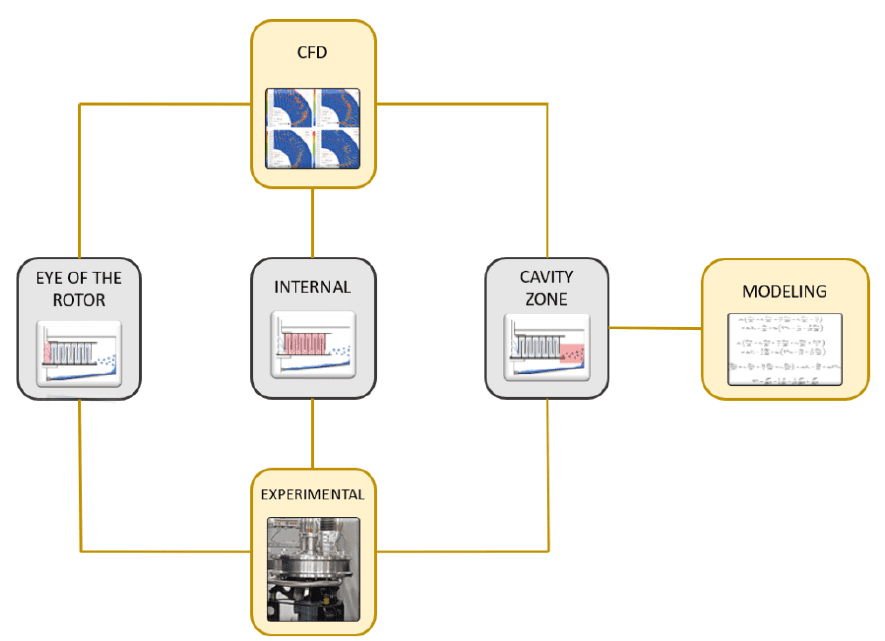

Most importantly, the rotation of the packing causes many difficulties regarding in-depth investigation of phenomena occuring inside it. Crucial process variables, such as liquid holdup, local dispersion of the phases, and even basic characteristics of the flow, cannot be measured directly. This, combined with the fact that such variables change over the packing’s radius due to changing field of flow and forces acting on elements of fluid, significantly hinders the researchers’ ability to model RPB processes.

Moreover, it has been extensively proven that mass transfer in the RPB is not limited to the rotating internal. A significant portion of the mass exchange process is occuring in the outer cavity zone, where the highly accelerated liquid phase contacts the gas phase in the form of fine spray. Lack of understanding of the phenomena occuring in the outer cavity zone also slows down the RPB technology to progress toward technological maturity.

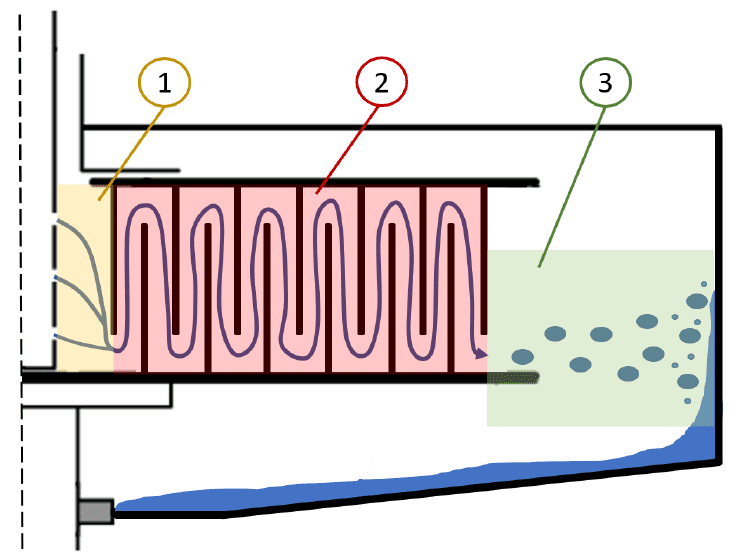

RPB can be divided into three basic zones:

1) The eye zone – in the eye of the rotor, where the liquid is sprayed onto the packing and subsequently accelerated by the centrifugal force

2) The packing zone – inside the rotor, where the gas and liquid are vigorously mixed inside a porous structure or on sets of baffles

3) The outer cavity zone – where the accelerated liquid contacts the gas as free droplets

© 2023 RPB Technology. All rights Reserved

created by: AlphaMedia