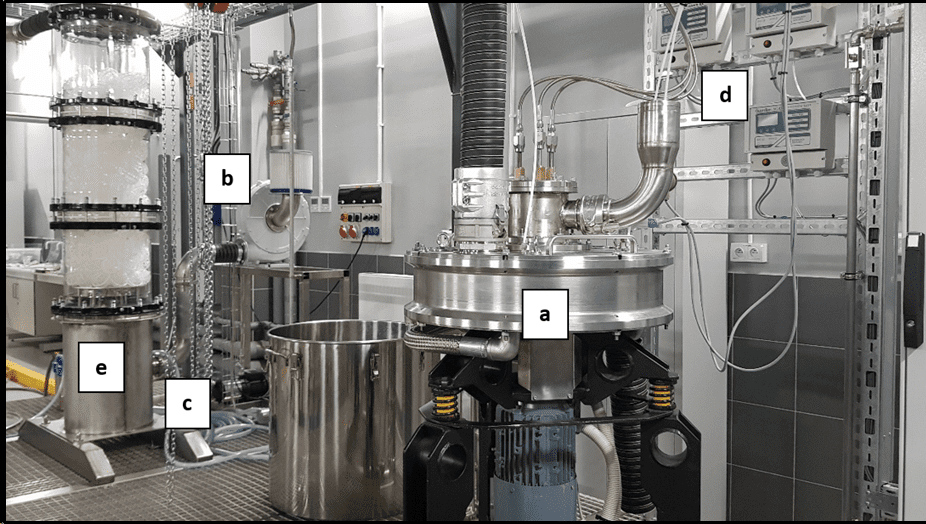

The RPB rig at Lodz University of Technology, Department of Process and Environmental Engineering, is designed for the investigation of absorption processes. Currently it is customized for carbon dioxide absorption, but can be extended to many other related processes.

a) RPB unit

b) fan blower

c) liquid pump

d) carbon dioxide detectors

e) gas humidifier column

Absorber with rotating packed bed (RPB)

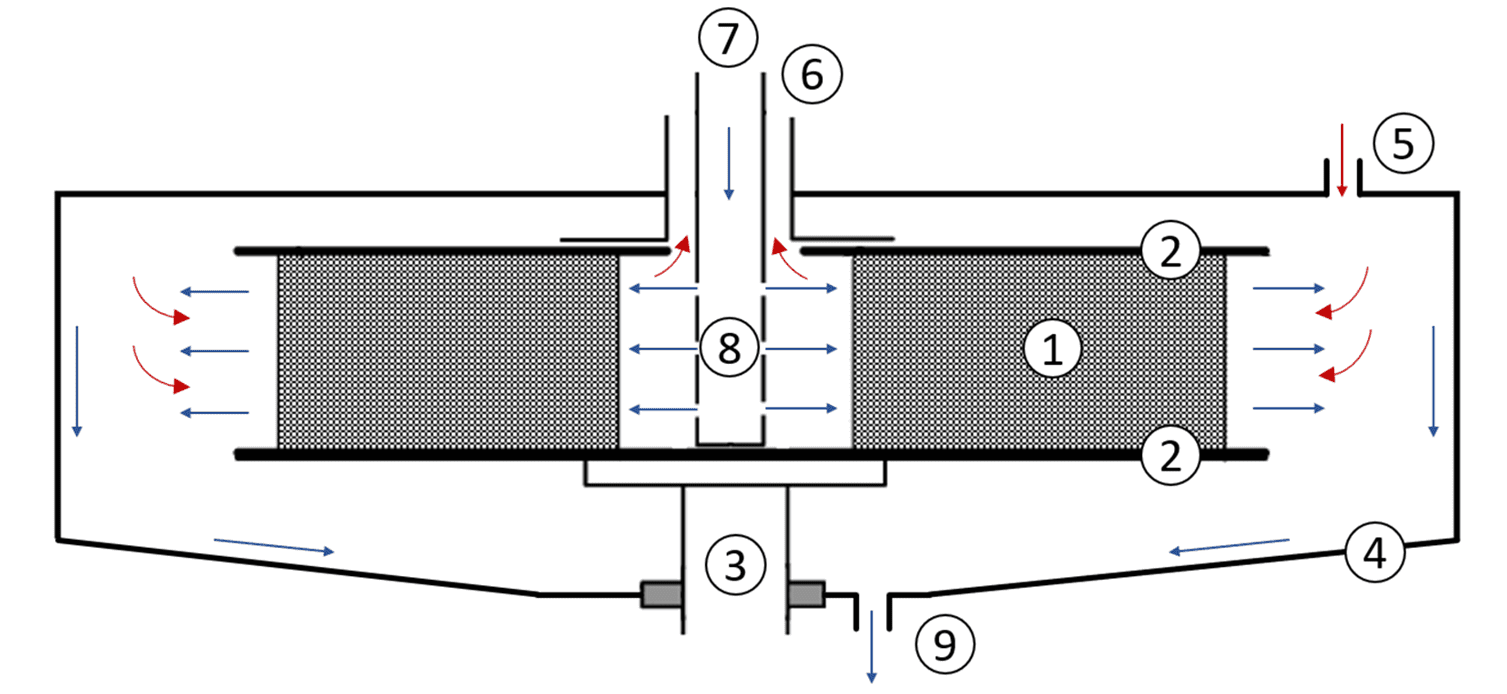

In these absorbers the liquid is brought into the centre of the rotor and under the influence of centrifugal force it flows through the packed bed radially outside. The centrifugal force (10÷1000 times higher than the gravity force) forces the flow of the liquid through the packed bed in the form of film or drops formed as a result of multiple atomisation. The absorbed gas is delivered to the external zone of the rotor, what forces the flow through the rotating packed bed and counter-flow contact with absorbent.

1) RPB packing

2) rotor plate

3) motor shaft

4) stationary casing

5) gas inlet

6) gas outlet

7) liquid inlet

8) liquid distributor

9) liquid outlet

Technological maturity level:

Despite the threshold of the technological maturity required by the industry is crossed, the RPB absorbers are still viewed as a “novelty” and the number of commercial applications is small, but quickly growing, e.g. in the area of absorption of valuable gaseous resources. The equipment owned by the team can provide basic and application research of RPB absorption to various industrial partners.

Technological advantage:

The development of the mass exchange surface and the high turbulence of flowing media lead to the significant increase of mass and heat exchange.

Potential benefits resulting from the application of RPB as an alternative for packed bed columns:

Application areas:

All industrial absorption processes of gaseous substances (NOx, SOx, H2S, CO2, acetone, ammonia, butadiene, benzene, chlorides etc.) in liquids.

Legal conditions:

No patent reservation (also due to the expiry) limiting the use of RPB devices. Now the protection of the constructional solutions and computational algorithms is realised through the confidentiality of information (know-how protection).

Form of cooperation:

The performance of tests at the Lodz University of Technology or at the company premises in RPB absorbers by means of semi-technical mobile plant (from December 2017). It is possible to adjust the specification of test apparatus at the premises of your company.

The Rotating Packed Bed Technology team is always open for research cooperation within the Academia. Our RPB equipment is designed for experimental investigation at the laboratory and pilot level.

We are constantly improving and developing our equipment in order to provide highest quality system for experimental investigation of RPB processes.

Our team specializes in:

Our team has worked with other academic facilities around Europe.

Much of the research and equipment design has been conducted in cooperation with the Technical University of Dortmund

The RPB Technology team is currently conducting a research project in cooperation with Brno University of Technology

The RPB team of Lodz University of Technology has been in close contact and cooperation with Prospin sp. z o.o., ever since its conception in 2020. The cooperation yields many networking opportunities and mutual scientific aid, combining strength of the Academia and the Industry.

© 2023 RPB Technology. All rights Reserved

created by: AlphaMedia