CarDiBi

An OPUS LAP WEAVE Project

Fundamental analysis of carbon dioxide absorption

from biogas in rotating packed beds

As fossil fuels become more scarce, while the demand for energy is constantly rising, the energy sector is on the lookout for alternative fuels and energy sources. While photovoltaic and wind are escellent candidates for large-scale electric power sources, it does not cover all the needs, especially in terms of heat production and energy storage.

With zero net carbon emmissions and abundance of natural substrates, biogas, that is methane produced by anaerobic fermentation of organic matter, is one of the main candidates for combating the climate change and growing energy demands. However, due to various fermentation by-products and their varying concentrations, the biogas technology needs development before large-scale production.

One of the main problems with the production of biogas is high concentration of carbon dioxide. Since CO2 is a product of combustion, it reduces energy density, and thus the overall quality of the product. Hydrogen sulfide, which is also produced through anaerobic fermentation, is not only problematic due to its smell, but is also toxic in higher concentrations. Therefore, in order to obtain the goal product (biomethane, >95% methane concentration), these by-products must be separated from the gas mixture.

Biogas refinement has been a subject of research for years, but until now, the selective absorption of the undesired by-product was carried out within stationary packed bed columns, which have limited capacity and low mass transfer efficiency. Within this project, we plan to investigate the fundamentals of biogas refinement through rotating packed bed absorption.

To tackle this issue, research teams from three universities teamed up to provide holistic and synergistic approach:

- The RPB team from Lodz University of Technology (Poland)

- The RPB team from Brno Technical University (Czech Republic)

- The RPB team from Berlin University of Technology (Germany)

Together, the teams have joined forces to research the following topics:

1. Screening of CO2/H2S absorbents suitable for RPB operation

2. Chemical and physicochemical investigation of chosen absorbents

3. Investigation of RPB hydrodynamics with novel structural packings

4. Development of a hydrodynamic model of the novel packings

5. Investigation of mass transfer efficiency with the use of the chosen solvents and new types of packing within an RPB unit (using simulated gas)

6. Development of an overall mass transfer model and its validation

7. Implementation of the RPB process of biogas refinement with the use of a novel, explosion-proof RPB absorption unit.

The interdisciplinary cooperation of the three teams will provide access to knowledge and experience of various experts in the topics of hydrodynamics, mass transfer and reaction kinetics.

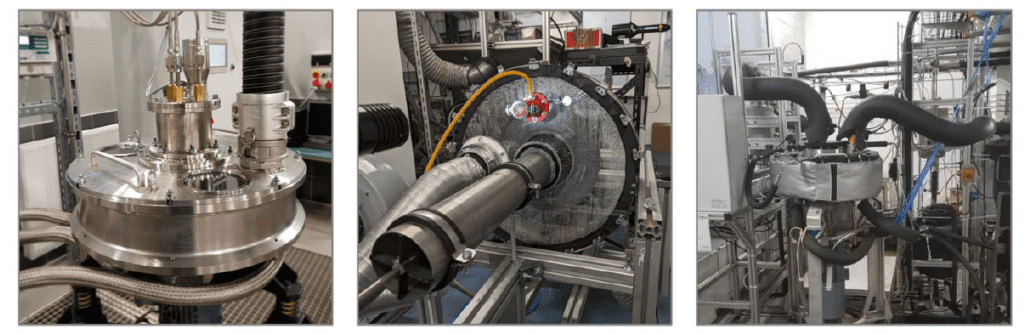

Each of the three teams owns their own RPB unit needed for carrying out the project (Lodz Team on the left, Brno team in the middle, Berlin team on the right)